Pipeline Perfection: 5 Reasons Service Saddles Are Your Ultimate Leak-Proof Solution

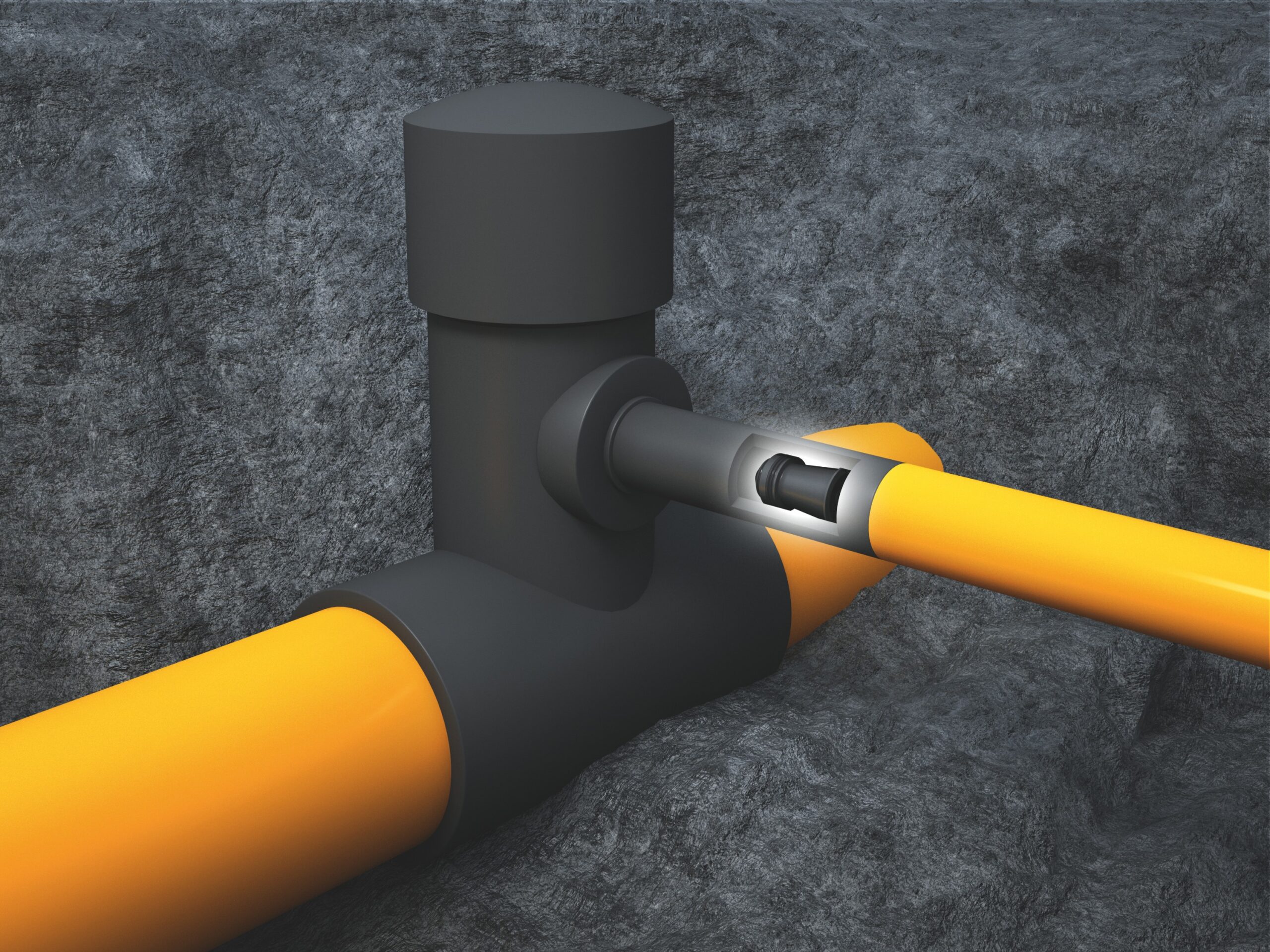

Pipelines are the unsung heroes of modern infrastructure ensuring everything from clean drinking water to fuel for our vehicles. But maintaining these crucial conduits can be a challenge especially when leaks occur. Enter service saddles—your reliable partners in achieving leak-proof pipelines. Here are five compelling reasons why service saddles should be your go-to solution for pipeline maintenance.

Fuss-Free Installation: Simplify Your Pipeline Repairs

When it comes to pipeline repairs, time is of the essence. The traditional methods of cutting or welding pipes can be labor-intensive, expensive and disruptive. Service saddles however offer a fuss-free installation process that bypasses these complications.

Save Time and Money

Service saddles are designed to be easily installed without the need for cutting or welding. This not only saves significant time but also reduces labor costs. The quick and straightforward installation process means less downtime for your pipeline minimizing disruptions to services and avoiding costly shutdowns.

Easy for Any Skill Level

The simplicity of installing service saddles means that even technicians with basic training can handle the job efficiently. This ease of use translates into faster repairs and a quicker return to normal operations making service saddles an invaluable tool in any pipeline maintenance arsenal.

Universal Compatibility: One Solution for All Pipe Types

One of the standout features of service saddles is their universal compatibility. Whether your pipeline is made of steel cast iron or PVC service saddles can adapt to various materials with ease.

Versatile Application

Service saddles are designed to work seamlessly with a wide range of pipe materials. This versatility makes them an ideal choice for diverse pipeline systems eliminating the need for multiple specialized repair tools. You can confidently use service saddles on different sections of your network knowing they will provide a secure and reliable connection every time.

Streamlined Inventory

With service saddles there’s no need to stockpile various types of repair fittings for different pipe materials. This simplifies your inventory management and ensures you always have the right tool on hand for any repair job. It’s an efficient and cost-effective solution that streamlines your maintenance processes.

Reliable Reinforcement: Strengthening Your Pipeline Connections

Service saddles not only facilitate repairs but also reinforce your pipeline connections. This added support ensures that your pipelines remain robust and resilient even under demanding conditions.

Secure Connections

Service saddles provide a tight and secure fit around the pipeline ensuring that connections are reinforced and less prone to leaks. This is particularly important for older pipelines that may have weakened over time. By adding a service saddle you enhance the structural integrity of the pipe preventing future leaks and prolonging its lifespan.

Support for New and Existing Lines

Whether you’re installing a new pipeline or reinforcing an existing one, saddles offer the support you need. They are designed to provide additional strength where it’s needed most, ensuring that your pipelines can withstand the pressures of daily use without compromising on performance.

Lasting Durability: Built to Withstand the Test of Time

Durability is a key consideration in pipeline repairs and service saddles excel in this area. Made from corrosion-resistant materials they are built to last ensuring that your repairs stand the test of time.

Corrosion-Resistant Materials

Service saddles are typically constructed from high-quality materials that resist corrosion such as stainless steel and durable polymers. This resistance to corrosion is crucial in preventing the degradation of the saddle and the pipeline especially in environments where the pipes are exposed to moisture or harsh chemicals.

Long Lifespan

Thanks to their robust construction, service saddles offer a long lifespan, making them a cost-effective solution for pipeline maintenance. You can rely on them to provide lasting repairs that reduce the need for frequent interventions, ultimately saving you time and money in the long run. For more information, visit https://blairsupplyusa.com website.

Code-Compliant Confidence: Meeting Industry Standards

Safety and compliance are paramount in pipeline maintenance and service saddles deliver on both fronts. They meet stringent industry standards giving you confidence in their performance and reliability.

AWWA Standards and NSF Certifications

Service saddles comply with the American Water Works Association (AWWA) standards and are certified by the National Sanitation Foundation (NSF). These certifications ensure that the saddles are safe for use in potable water systems and meet the high standards required for public health and safety.

Peace of Mind

Using code-compliant service saddles provides peace of mind knowing that your repairs adhere to industry regulations. This compliance not only ensures the safety and reliability of your pipeline system but also helps avoid potential legal and regulatory issues that could arise from using substandard repair fittings.

Fun Fact: The History of Service Saddles

Did you know that the concept of service saddles dates back to the early 20th century? Engineers sought a reliable method to repair and tap into pipelines without extensive downtime. The first service saddles were rudimentary compared to today’s advanced designs but they laid the groundwork for the efficient and versatile solutions we have now.

Embrace the Future of Pipeline Maintenance

Service saddles are your ultimate leak-proof pipeline partners offering fuss-free installation, universal compatibility, reliable reinforcement, lasting durability and code-compliant confidence. By incorporating service saddles into your pipeline maintenance strategy you can ensure efficient cost-effective and long-lasting repairs that keep your pipelines functioning optimally.

Water Damage Restoration: Your Essential Guide

Water damage can strike unexpectedly, wreaking havoc on homes and businesses. Whether it’s caused by natural disasters, plumbing failures, or appliance malfunctions, swift and effective water damage restoration is crucial to minimize long-term damage and associated costs. Here’s a comprehensive guide to understanding the importance of water damage restoration and the steps involved in the process.

The Importance of Timely Water Damage Restoration

Time is of the essence when dealing with water damage. Delays in addressing the issue can lead to severe structural damage, mold growth, and health risks. Mold, in particular, can begin to develop within 24 to 48 hours in a damp environment, posing significant health hazards, especially to those with respiratory conditions. Prompt water damage restoration ensures that moisture levels are controlled, preventing these secondary problems. Integrating these measures helps maintain a dry and safe home, crucial for preventing long-term damage and ensuring the health and safety of the occupants.

Key Steps in Water Damage Restoration

1. Assessment and Inspection:

The first step in the water damage restoration process is a thorough assessment and inspection of the affected area. Professionals use advanced tools like moisture detectors and infrared cameras to identify the extent of water infiltration and damage. This step is crucial for developing an effective restoration plan.

2. Water Removal:

Once the assessment is complete, the next step is to remove standing water. Industrial-grade pumps and vacuums are used to extract water quickly, preventing further saturation of building materials and reducing drying time. Efficient water removal also helps in minimizing the risk of mold growth.

3. Drying and Dehumidification:

After water extraction, the drying and dehumidification process begins. High-powered air movers and dehumidifiers are deployed to remove any remaining moisture from walls, floors, and furniture. This step is critical to ensure that hidden moisture pockets are addressed, as they can lead to mold growth and structural issues if left untreated.

4. Cleaning and Sanitizing:

Water damage can bring contaminants into the affected area, making cleaning and sanitizing an essential part of the restoration process. Professionals use specialized cleaning products and techniques to disinfect the area, ensuring it is safe for occupancy. Personal belongings and furniture may also be cleaned and restored, depending on the extent of the damage.

5. Restoration and Repair:

The final step in the water damage restoration process involves repairing and restoring the property to its pre-damage condition. This may include minor repairs such as replacing drywall and carpet or major reconstruction efforts, depending on the severity of the damage. The goal is to make the affected area look as if the damage never occurred.

Preventing Future Water Damage

While immediate response to water damage is crucial, taking steps to prevent future incidents is equally important. Regular maintenance of plumbing systems, roof inspections, and ensuring proper drainage around the property can significantly reduce the risk of water damage. Additionally, investing in water detection devices and a sump pump can provide early warnings and solutions to potential water issues.

Water damage restoration is a critical service that requires prompt and professional attention. By understanding the process and the importance of each step, homeowners and business owners can ensure their properties are restored efficiently and effectively. Taking preventive measures can further safeguard against future water damage, providing peace of mind and protection for valuable assets.